Download hi-res photo

New CM (checkweigher and metal detector) combination system from Mettler-Toledo

Download hi-res photo

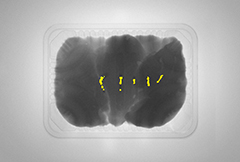

Mettler-Toledo's X36 DXD+ x-ray system offers unrivalled detection of hard-to-find contaminants

January 9, 2025 – Mettler-Toledo Product Inspection Group will exhibit a wide range of inspection technologies in booth #C24159 at the International Production & Processing Expo (IPPE), being held in Atlanta, Jan 28-30, 2025. These world-class x-ray systems, metal detectors, checkweighers and vision systems help meat, poultry and animal feed processors and packers ensure food safety, maintain product quality and protect brand reputation.

“Cost pressures and operational challenges continue to impact meat and poultry processors on multiple levels,” said Thomas Koshy, Sales Director at Mettler-Toledo Product Inspection – Americas. “We're responding by advancing our technology for superior quality control and regulatory compliance, while simultaneously making our systems more affordable and easier to use through streamlined design and unified components. Additionally, our enhanced automation and training resources help customers maintain high standards even when facing staffing challenges.”

At IPPE, Mettler-Toledo will feature their new X52 dual energy x-ray inspection system, which delivers advanced detection capabilities at an attractive price point. To optimize performance for each application, the X52's proprietary software offers increased flexibility by seamlessly transitioning between single energy, dual energy or both modes. Also on display is the X36 DXD+, which offers unrivalled detection of hard-to-find contaminants such as calcified bone in textured and overlapping product applications.

Another highlight will be the new CM (checkweigher and metal detector) combination system. With unparalleled flexibility, Mettler-Toledo’s combination systems are available for many budgets and in a variety of configurations including an all-in-one checkweigher/vision/x-ray/metal detector system that provides comprehensive quality control in a single unit.

The vision solution on exhibit will be Mettler-Toledo’s V31. This system verifies the integrity of graphics, reads and verifies 1D and 2D codes and inspects alpha-numeric characters to prevent labeling errors and ensure consistent quality.

For metal detection, Mettler-Toledo will showcase the Profile Advantage with a conveyor designed specifically for meat and protein applications, engineered with stainless-steel construction, tool-less removable components and more to withstand harsh washdowns. A Profile Advantage pipeline metal detector, designed to inspect liquids, slurries and purees, will also be on exhibit.

Also shown will be the C35 washdown AdvancedLine checkweigher, which rejects under- and overweight packages to ensure legal weight requirements are met while reducing product giveaway. Featuring powerful FlashCell™ EMFR technology, the C35 maximizes accuracy at throughputs of up to 800 packages per minute, and its full IP69 rating provides protection against caustic detergents and high-pressure cleaning.

All systems on exhibit will be connected to ProdX™, Mettler-Toledo's advanced connectivity and data management solution. Based on Industry 4.0 principles of secure machine-to-machine communication, ProdX helps digitalize food safety compliance, reduce auditing time and facilitate faster product recalls through its enhanced web dashboard capabilities.

About METTLER TOLEDO

METTLER TOLEDO is a leading global manufacturer of precision instruments and a service provider. The company ranks highly in a number of market segments and is a global market leader in many areas. METTLER TOLEDO is one of the largest providers of weighing systems and analysis instruments for use in laboratories and in-line measurement within demanding industrial and food production processes.

The Product Inspection division of METTLER TOLEDO is one of the leading providers within the field of automated inspection technology. The division includes the following brands: Safeline metal detection and X-ray inspection, Garvens and Hi-Speed checkweighers, and CI-Vision machine vision systems. The product inspection solutions improve manufacturers’ process efficiency and help them comply with industry standards and regulations. METTLER TOLEDO systems ensure consistently higher product quality, helping protect both consumers as well as the reputation of manufacturers and their products and brands.

For more information, please visit: www.mt.com/pi

Sarrina Crowley

METTLER TOLEDO Product Inspection

1571 Northpointe Parkway

Lutz, FL 33558 USA

Tel: +1 813 889 9500

[email protected]

www.mt.com/pi

Cat McBride

McBride Public Relations

527 27th Street

Richmond, CA 94804 USA

Tel: +1 650 384 5727

[email protected]

www.mcbridepr.com